Injection Molding

In injection molding, material is fed through a hopper into a barrel where a reciprocating screw mixes and melts the material then injects it into a mold.

Narrow Your Injection Molding Search

ESSENTIAL READING

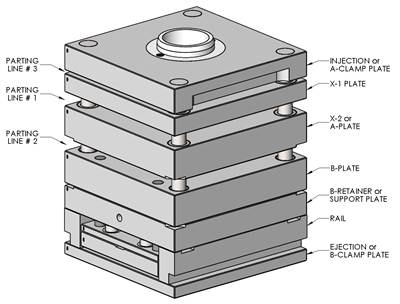

VIEW ALLHow To Design Three-Plate Molds – Part 4

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs — and keep the customer happy.

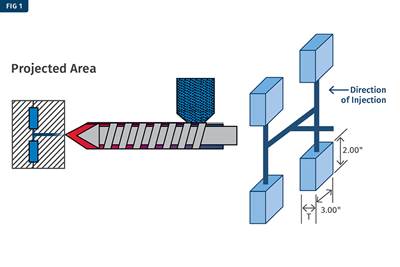

Read MoreIs There a More Accurate Means to Calculate Tonnage?

Molders have long used the projected area of the parts and runner to guesstimate how much tonnage is required to mold a part without flash, but there’s a more precise methodology.

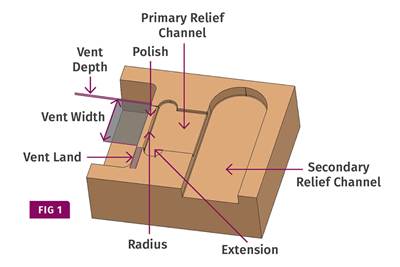

Read MoreBack to Basics on Mold Venting (Part 2: Shape, Dimensions, Details)

Here’s how to get the most out of your stationary mold vents.

Read MoreBack to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.

Read MoreHow to Design Three-Plate Molds, Part 1

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs, and keep the customer happy.

Read MoreHot Runners: How to Maintain Heaters, Thermocouples, and Controls

I conclude this three-part examination of real-world problems and solutions involving hot runners by focusing on heaters, thermocouples, and controls. Part 3 of 3.

Read MoreLatest Injection Molding News And Updates

StackTeck Establishes iMFLUX Center of Excellence

The Canadian maker of high-volume molds reached out to Procter & Gamble for permission to use and share information on low-pressure iMFLUX technology after success using it to qualify a range of postconsumer recycled (PCR) resins.

Read MoreU.S. Debut for Slimmed Down Electric Machine

NPE2024: Arburg’s debut of the 310-ton Allrounder 720 E Golden Electric extends the tonnage range of the electric series and marks the first global press premiere outside of Germany.

Read MoreMold Solutions Target Safety, Storage and Productivity

NPE2024: Globeius and its suppliers showcase solutions focused on decreasing downtime, reducing energy consumption, increasing safety and more in an injection mold shop.

Read MoreCompletely Connected Molding

NPE2024: Medical, inmold labeling, core-back molding and Industry 4.0 technologies on display at Shibaura’s booth.

Read MoreAutomated Injection Molding Process Adjustments

Shibaura says its S-Concept represents an AI technology capable of making real-time process adjustments.

Read MoreEnhanced Temperature Controls for Hot Runners, Extrusion and Packaging

NPE2024: Athena introduces expanded hot-runner controller with up to 120 zones, plus updated panel-mount “universal” temperature/process control.

Read MoreFeatured Posts

Industry 4.0 and AI in the Spotlight for Shibaura

Shibaura is deploying its exclusive industrial IoT service machiNetCloud at NPE2024 and launching the all-new S-Concept AI system for making real-time process adjustments.

Read MoreAthena Controls Emphasizes Customization: Buy Just What You Need

At NPE, 60-year-old Athena reintroduces itself as a vendor of standard control platforms customized for maximum utility and economy.

Read MoreArburg Debuts New Machine Outside of Germany for First Time

NPE2024: Arburg says the Allrounder 720 E injection molding machine premiere highlights the importance of the show and market.

Read MoreConsistent Shots for Consistent Shots

An integral supplier in the effort to fast-track COVID-19 vaccine deployment, Retractable Technologies turned to Arburg and its PressurePilot technology to help deliver more than 500 million syringes during the pandemic.

Read MoreMolding Solutions for Flexibility and Monitoring

NPE2024: Ewikon highlighting new hot runner nozzle and Smart Control system.

Read MoreAbsolute Robot Grips New Role as Custom Automation Integrator

NPE2024: ARI exhibit positions robot supplier as integrator of more complex custom downstream automation systems.

Read MoreFAQ: Injection Molding

Plastic injection molding is a cyclical manufacturing process that allows for cost-efficient production of a mass number of identical parts made from either thermoplastic or thermoset materials.

Cushion values in injection molding ultimately are an indication of a part’s quality, especially its dimensions. A consistent cushion will create consistent part dimensions.

It is important to determine which type of bubble your part has, and what the root cause might be. Determining bubble type will allow you to pinpoint the source and determine your next course of action to eliminate the problem.

Most molders are still relying on “general-purpose” screw designs that go back 30 years. With all of the technical improvements that have been made on machines over that time, nothing has been done to improve melt uniformity. We still use “general-purpose” (GP) screws, which well-known screw designer Bob Dray wisely has called “no-purpose” screws. That is they do not melt plastic uniformly. Processing with a uniformly melted plastic would seem like a high priority, but it has seen little if any attention.

Injection Molding Supplier Categories

- Thermoformers

- Injection Molding Machines

- Platens

- Thermoforming Molds

- Extrusion Blow Molding Machines

- Pre-expanders, Polystyrene Bead

- Trimmers, Deflashers for Blow Molding

- Stretch-Blow Molding Machines

- Nonferrous Metals for Molds

- Mold/Die Management Systems

- Injection Molds

- Mold Steels

- Injection Blow Molding Machines

- Dip-Blow or Compression-blow Molding Machines

- Cutting, Stamping, Trimming Dies

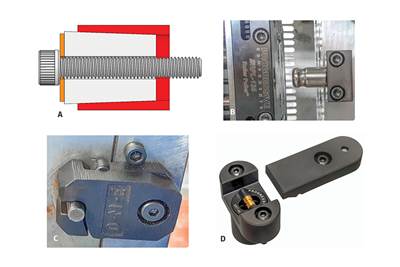

- Quick-mold-change Equipment

- Mold Making and Repair Equipment

- Injection Molding Nozzles

- Parison Programmers

- Mold Components

- Injection Blow Molds

- Presses, Polystyrene Bead

- Spray Coating Systems (for Bottles)

- Rotational Molds

- Inserts

- Accumulators (Melt)

- Structural Foam Machines (for Thermoplastics)

- Injection Molding Non-return Valves

- Mold Evacuation Systems

- Mold Grease

- Rotational Molding Machines

- Compression/Transfer Molds

- Mold-cleaning and Maintenance Chemicals

- Nonmetallic Tooling Materials

- Hot Runner Components

- Foam Molds

- Compression/Transfer Presses

- Prototype Molds

(2).jpg;maxWidth=300;quality=90)

(1).jpg;maxWidth=970;quality=90)